How to Make a Model Steam Engine

The reader who has succeeded in putting together the simple engine described in the preceding chapter may wish to try his hand on something more ambitious in the same line. The engine illustrated in Figs. 53 to 66 will give sufficient scope for energy and handiness with drill and soldering iron. The writer made an engine of the same kind, differing only from that shown in the design of the crosshead guides, without the assistance of a lathe, except for turning the piston and fly wheel - the last bought in the rough. Files, drills, taps, a hack saw, and a soldering iron did all the rest of the work.

Solder plays so important a part in the assembling of the many pieces of the engine that, if the machine fell into the fire, a rapid disintegration would follow. But in actual use the engine has proved very satisfactory; and if not such as the highly-skilled model-maker with a well-equipped workshop at his command would prefer to expend his time on, it will afford a useful lesson in the use of the simpler tools. Under 50 lbs. of steam it develops sufficient power to run a small electric-lighting installation, or to do other useful work on a moderate scale.

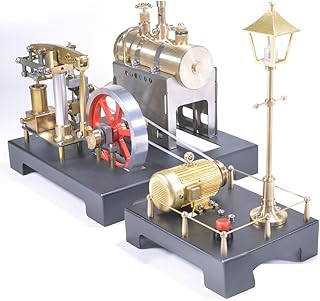

Fig. 53. - Elevation of a large horizontal engine.

The principal dimensions of the engine are as follows ;-

Bedplate (sheet zinc), 13-1/2 inches long; 4-1/2 inches wide; 1/8 inch thick.

Support of bedplate (1/20 inch zinc), 3 inches high from wooden base to underside of bedplate.

Cylinder (mandrel-drawn brass tubing), 1-1/2 inches internal diameter; 2-13/16 inches long over all.

Piston, 1-1/2 inches diameter; 1/2 inch long.

Stroke of piston, 2-1/4 inches.

Connecting rod, 5 inches long between centres; 5/16 inch diameter.

Piston rod, 5-1/8 inches long; 1/4 inch diameter.

Valve rod, 4-1/8 inches long; 3/16 inch diameter.

Crank shaft, 5 inches long; 1/2 inch diameter.

Centre line of piston rod, 1-1/4 inches laterally from near edge of bed; 1-5/8 inches from valve-rod centre line; 1-5/8 inches vertically above bed.

Centre line of crank shaft, 10-3/8 inches from cross centre line of cylinder.

Bearings, 1 inch long.

Eccentric, 9/32-inch throw.

Fly wheel, diameter, 7-1/2 inches; width, 1 inch; weight, 6 lbs.

Pump, 3/8-inch bore; 3/8-inch stroke; plunger, 2 inches long.

Fig. 54. - Plan of a large horizontal engine

Other dimensions will be gathered from the various diagrams of details.

The reader will, of course, suit his own fancy in following these dimensions, or in working to them on a reduced scale, or in modifying details where he considers he can effect his object in a simpler manner.

The diagrams are sufficiently explicit to render it unnecessary to describe the making of the engine from start to finish, so remarks will be limited to those points which require most careful construction and adjustment.

The Bedplate. - This should be accurately squared and mounted on its four arch-like supports. (For dimensions, consult Fig. 55.) Half an inch is allowed top and bottom for the turnovers by which the supports are screwed to the bedplate and base. The ends of the longer supports are turned back so as to lie in front of the end supports, to which they may be attached by screws or solder, after all four parts

Fig. 55. - Standards of Bedplate

have been screwed to the bed. Care must be taken that the parts all have the same height. Drill all holes in the turnovers before bending. Use 1/8-inch screws. Turn the bed bottom upwards, and stand the four supports, temporarily assembled, on it upside down and in their correct positions, and mark off for the 3/32-inch holes to be drilled in the bed. A hole 3/4 inch in diameter should be cut in the bedplate for the exhaust pipe, round a centre 2 inches from the end and 1-5/8 inches from the edge on the fly-wheel side, and two more holes for the pump.

Making the Cylinder Slide and Valve. - The cylinder barrel must be perfectly cylindrical and free from any dents. Mandrel-drawn brass tubing, 1/16-inch thick, may be selected. If you cannot get this turned off at the ends in a lathe, mark the lines round it for working to with the aid of a perfectly straight edged strip of paper, 2-13/16 inches wide, rolled twice round the tube. The coils must lie exactly under one another. Make plain scratches at each end of the paper with a sharp steel point. Cut off at a distance of 1/16-inch from the lines, and work up to the lines with a file, finishing by rubbing the ends on a piece of emery cloth resting on a hard, true surface.

FIG. 56.- Cylinder standard before being bent.

A square-cornered notch 1/8 inch deep and 7/8 inch wide must now be cut in each end of the barrel, the two notches being exactly in line with one another. These are to admit steam from the steam ways into the cylinder.

Cylinder Standards. - Use 5/64 or 3/32 inch brass plate for these. Two pieces of the dimensions shown in Fig. 56 are needed. Scratch a line exactly down the middle of each, and a cross line 1/2 inch from one end. The other end should be marked, cut, and filed to a semicircle. Drill three 3/16-inch holes in the turnover for the holding-down screws. The two standards should now be soldered temporarily together at the round ends and trued up to match each other exactly. Place them in the vice with the bending lines exactly level with the jaws, split the turnovers apart, and hammer them over at right angles to the main parts. Whether this has been done correctly may be tested by placing the standards on a flat surface. Take the standards apart, and scratch a cross line on each 1-5/8 inch from the lower surface of the foot on the side away from the foot. Make a punch mark where the line crosses the vertical line previously drawn, and with this as centre describe a circle of the diameter of the outside of the barrel. Cut out the inside and file carefully up to the circle, stopping when the barrel makes a tight fit. On the inside of the hole file a nick 1/8 inch deep, as shown in Fig. 56. Remember that this nick must be on the left of one standard and on the right of the other, so that they shall pair off properly.

Standards and barrel must now be cleaned for soldering. Screw one standard down to a wood base; slip one end of the barrel into it; pass the other standard over the other end of the barrel, and adjust everything so that the barrel ends are flush with the, outer surfaces of the standard, and the nicks of the barrel in line with the standard nicks. Then screw the other standard to the base. Solder must be run well into the joints, as these will have to stand all the longitudinal working strain.

The next step is the fitting of the cylinder covers. If you can obtain two stout brass discs 2-1/8 inches in diameter, some trouble will be saved; otherwise you must cut them out of 3/32-inch plate. The centre of each should be marked, and four lines 45 degrees apart be scratched through it from side to side. A circle of 15/16- inch radius is now drawn to cut the lines, and punch marks are made at the eight points of intersection. Solder the covers lightly to the foot side of their standards, marked sides outwards, and drill 1/8- inch holes through cover and standard at the punch marks. Make matching marks on the edges. Unsolder the covers, enlarge the holes in them to take 5/32-inch screws; and tap the holes in the standards. This method will ensure the holes being in line, besides avoiding the trouble of marking off the standards separately.

Bore a 1/4-inch hole in the centre of one cover--be sure that it is the right one--for the piston rod.

You can now proceed to the making of the piston-rod gland (Fig. 54, G1). Fig. 57 shows how this is built up of pieces of tubing and brass lugs for the screws. If possible, get the tubular parts trued in a lathe.

FIG. 57. - Vertical section of cylinder.

Before the gland is soldered to the cover, the cover should be put in place, the piston rod attached to the piston, and the parts of the gland assembled. Push the piston rod through the cover until the piston is hard up against the back of the cover. Slip the gland over the rod, turn it so that the screws are parallel to the foot of the standard, and make the solder joint. This is the best way of getting the gland exactly concentric with the cylinder so that the piston rod shall move without undue friction. But you must be careful not to unsolder the cylinder from its standard or the parts of the gland. Blacken the piston rod in a candle flame to prevent solder adhering.

Steam Chest. - The walls of the steam chest are best made in one piece out of 1/2-inch brass by cutting out to the dimension given in Fig. 58. A sharp fret saw will remove the inside rectangle. Get both inside and outside surfaces as square as possible in all directions, and rub down the two contact faces on emery cloth supported by an old looking-glass.

FIG. 58.- Wall-piece for steam chest, with gland and valve rod in position.

Two perfectly flat plates of 1/8-inch brass are cut to the size given in Fig. 59, or a little longer both ways, to allow for working down to the same area as the wall-piece. This operation should be carried out after soldering the three pieces together. File and rub the sides until no projections are visible. Then drill twelve 3/32-inch holes right through the three parts. After separating them, the holes in the walls and what will be the cover must be enlarged to an easy fit for 1/8-inch bolts, and the valve plate tapped.

Now drill 3/16-inch holes centrally through the ends of the walls for the valve rod. If the first hole is drilled accurately, the second hole should be made without removing the drill, as this will ensure the two holes being in line. If, however, luck is against you, enlarge the holes and get the rod into its correct position by screwing and soldering small drilled plates to the outside of the chest. Also drill and tap a hole for the lubricator. The attachment of the gland (Fig. 54, G2) is similar to that of the cylinder gland, and therefore need not be detailed.

The Valve Plate (Fig. 59). - Three ports must be cut in this - a central one, 7/8 by 3/32 inch, for the exhaust; and two inlets, 7/8 by 3/32 inch, 1/8 inch away from the exhaust. These are easily opened out if a series of holes be drilled along their axes.

FIG. 59. - Valve plate.

The Steam Ways. - The formation of the steam ways between valve plate and cylinder is the most ticklish bit of work to be done on the engine as it entails the making of a number of solder joints close together.

FIG. 60. - Piece for steam ways.

We begin by cutting out of 1/20-inch sheet brass a piece shaped as in Fig. 60. Parallel to the long edges, and 3/8 inch away, scribe bending lines. Join these by lines 5/8 inch from the short edges, and join these again by lines 1/4 inch from the bending lines. Cuts must now be made along the lines shown double in Fig. 60. Bend parts CC down and parts BB upwards, so that they are at right angles to parts AA. The positions of these parts, when the piece is applied to the cylinder, are shown in Fig. 62.

FIG. 61. - Valve plate and steam ways in section.

One must now make the bridge pieces (Fig. 61, a, a) to separate the inlet passages from the exhaust. Their width is the distance between the bent-down pieces CC of Fig. 60, and their bottom edges are shaped to the curvature of the cylinder barrel. Finally, make the pieces bb (Fig. 61), which form part of the top of the steam ways. In the assembling of these parts a blowpipe spirit lamp or a little "Tinol" soldering lamp will prove very helpful. The following order should be observed:-

(1.) Solder the piece shown in Fig. 60 to the

FIG. 62.-Cross section of cylinder and valve chest.

cylinder barrel by the long edges, and to the cylinder supports at the

ends. This piece must, of course, cover the steam ports in the

cylinder.

(2.) Put pieces aa (Fig. 61) in position, with their tops quite flush

with the tops of BB (Fig. 62), and solder them to the cylinder barrel

and sides of the steam-way piece.

(3.) Solder the valve plate centrally to BB, and to the tops of aa,

which must lie between the central and outside ports. Take great

care to make steam-tight joints here, and to have the plate parallel to

the standards in one direction and to the cylinder in the other.

(4.) Solder in pieces bb. These should be a tight fit, as it is

difficult to hold them in place while soldering is done.

(5.) Bore a 5/16-inch hole in the lower side of the central division

and solder on the exhaust pipe.

Slide Valve Engine - Part 2 >>>>

List of Chapters in this book: Sawing Trestle | Joiner's Bench | Bookstand | House Ladder | Developing Sink | Poultry House | Bicycle Shed | Rifle Target | Cabinet Making | Telegraphic Apparatus | Electric Motor | Alarm Clock | Model Railway | Reciprocating Engine | Slide Valve Engine | Model Steam Turbine | Steam Tops | Model Boilers | Quick Boiling Kettle | Hot Air Engine | Water Motor | Model Pumps | Kites | Paper Gliders | Model Aeroplane | Scientific Apparatus | Rain Gauge | Wind Vanes | Strength Tester | Harmonographs | Automatic Matchbox | Wooden Workbox | Wrestling Puppets | Double Bellows | Pantograph | Silhouette Drawing Machine | Signalling Lamp | Miniature Gasworks